Jeepskate's Joint

About Me

Links

Trail Run Pics

Tech Articles

Jeepskate:

Suspension

Steering

Drivetrain

Body/Interior

Jeepskate

II/XL:

Suspension

Steering

Drivetrain

Body/Interior

1 Last

7:

Suspension

Steering

Drivetrain

Body/Interior

Drivetrain

The Jeep started out with an original 258/T-999 auto/Dana 300 combo with a Dana 30 front axle and semi-rare factory Dana 44 rear with 3.31 gears. Since this isn't a radical hardcore trail rig, the plan is just to enhance what's there. When I bought the Jeep, the original 258 had a fair amount of valvetrain noise and oil leaks at the valve cover and main seal. While my past experiences with the 258 told me that they are indeed very tough engines that'll keep running when lesser engines have given up the ghost, I knew that one day it too would die. Shortly after buying the Jeep, I came across a guy in Michigan who had swapped in a 350 and GM powertain and was just looking to get rid of the original 1985 parts quickly to free up the garage space for the paltry sum of $100. So, I contacted my buddy Matt Kievit out in Michigan and made arrangements for him to pick up the powertrain for me in exchange for the Dana 300 (all I really wanted was the engine and auto trans). The next time that he was headed in my direction on a parts run, he dropped the engine & trans off at my house. In the meantime I had the carb rebuilt, did a Nutter bypass, and swapped in a Ford cap & rotor and TFI coil. I also made a failed attempt at installing a Trans-Go shift kit and ended up swapping in the valve body from the spare trans in order to get back on the road, and installed a Mopar deep trans pan with drain plug and poly trans mount bushings (Do *not* waste your time with the included gasket...it is junk. Get a cork gasket or even better the new Mopar re-usable plastic gasket.). During the summer of 2002, I started getting emissions test notices from the state and figuring that the original 258 probably wouldn't survive the dyno test this time, I put the spare engine up on the engine stand and started tearing it down. With Matt's guidance I purchased some of the parts to rejuvenate the bottom end, then made plans to head out to his place one Saturday in August to do the assembly. I degreased the block, strapped it to the hitch-hauler behind the Durango, packed up my boxes of parts, and headed east. The cylinders & rings looked good, so we left them alone and installed new main bearings, main seal, CompCams cam, Summit lifters, Napa timing set, oil pump & pickup, 4.0 oil pan gasket (don't waste your time with the multi-piece 4.2 gasket), and I bought a rebuilt '89 head that Matt had sitting on a shelf in the bag from the rebuilder. When I returned home, I installed the head (had to use a couple of GM spacers, same as for a 4.0 head swap), rockers, valve cover, fuel pump and manifolds. I ended up having to go through emissions testing in October before I had time to swap engines, and that was the end of the line for the original engine...it made all sorts of noises and billowed smoke in the test bay, failed of course, and made the drive back home, but promptly seized up the next morning when I went to leave for work. I called in to let my supervisor know what happened and that I wouldn't be in and he informed me that there was a meeting and he would call me back in a bit to conference me in...turns out they had finally announced that morning that the company (the main consumer of my Jeep wrenching time) would be shutting down. What a day!! A couple of days later, the doctor found tumors in my wife's uterus and informed her that she'd have to have a hysterectomy, so I bought a used Grand Cherokee and the Jeep promptly dropped to about my lowest priority and sat in the driveway until the Spring of 2003.

I began tearing the Jeep down in May 2003 and dropped the fresh engine in over the Memorial Day weekend along with a new set of poly engine mounts. The fuel lines didn't look so good, so I replaced them with stainless steel lines from Inline Tube and EFI rated hose & clamps from Napa (thinking ahead and keeping my options open) and new filler hoses from Krage Motorsports. As the company went deeper into shutdown mode (and I looked for a new job in a crappy market), I had less time to devote to the Jeeps, and things slowed down again. I had intended to be done in about a month, and as I'm writing this I'm coming up on a year (fortunately I was only unemployed for a month and picked up some side jobs during that time). I bought a twin-stick and an unused AA clocking ring off Ebay and had also purchased a complete 4.0 head and EFI setup. I later decided that I didn't want to go through the work of installing the head and hacking into the wiring harness, so I traded it for the custom front bumper and 203 range box machining for the Scrambler, and decided I would just do a simpler TBI setup. I almost got in on a group buy for the Howell TBI kit, but had promised my son a dirt bike for his birthday and figured it would be wiser to buy that while I had the cash. Then I started hearing a bit more about Megasquirt, which is a DIY approach. You purchase the components for the controller (or buy one already assembled from another source), the injection system and fuel pump of your choice, and download the free software to program the controller (commonly done with a laptop). So, I've pretty much decided to go that route after I get the Jeep running solidly with the carb. I've already purchased a used TBI throttle body off Ebay from an '88 Caprice 4.3 and will be adapting it to the stock intake manifold with a Trans-Dapt TRD-2086 or Mr. Gasket MRG-1937 (these are the same adapters used for the popular Motorcraft 2100 swap). In the meantime I've purchased an unused National Carburetor fully rebuilt Carter BBD to get up & running with (the original carb was starting to act up again just before the engine seized and I don't want to deal with a bunch of known possible problems as I'm trying to get up & running again). I had had a new muffler & tailpipe installed by Exhaust Works already, so I installed a new catalytic converter & head pipe from 4WD Hardware. The studs were missing from the exhaust manifold, so I bought new studs & hardware from McMaster-Carr for attaching the head pipe (they've become a valuable resource for some of the hardware and consumables that I've needed on this project and since they have a local warehouse I usually get everything I order the next day). With the clocking and the shackle reversal, I'll probably need to have my front driveshaft modified or replaced (I'll probably get a replacement built and store the original with the rest of the original take-off parts). I'm going to leave the stock gearing at least for now and see how the Jeep behaves and am debating whether or not to remove the Trac-Loc from the Scrambler and put it in the rear which would put the Jeep at full factory option. I also installed the Navajo power brake setup from Off-Again, which is basically a GM dual-diaphragm booster retro-fit, and some Speed Bleeders. I replaced all of the brake hoses with new Crown parts from 4WD Hardware and added some GM extension hoses from NAPA (I bought the new hoses before I decided to add the additional lift).

With the Jeep on the road now, there will definitely be some changes and progress. The rebuilt carb I used was only flowing gas from one venturi, so I yanked it off and put the old carb back on. Runs like crap, but it runs. I'll probably rebuild one of the carbs to tide me over until I'm ready to tackle the EFI project. I had some problems with the trans not shifting properly which were sorted out by adjusting the throttle linkage. A lot of people refer to it as the kickdown linkage, but this is a bit of a misnomer for at least the T-999. This lever is actually continually adjusted through the motion of the linkage assembly and it in turn continuously adjusts the pressure in the trans. It is critical that this is setup & adjusted properly or you risk burning up the clutches...I'm hoping that I didn't damage mine (of course I *do* have a spare). The trans is running a little warmer than I'd like (a fair amount of hunting while cruising and I'm working it pretty hard accelerating due to the stock gears & 35's) so I'm adding a Derale remote transmission cooler and regearing to 4.10's (already had a set for the rear, just bought a set for the front, front carrier, and the install kits...going to put the EZ-Locker that was originally going into Jeepskate in as well). Also having a problem with the tranny pan leaking...the thin gasket that came with the Mopar deep pan is junk and I didn't have very good luck with a cork gasket, so I picked up a Mopar re-usable gasket to try out. I also picked up a higher ratio throttle lever arm which is supposed to firm up the 1-2 upshift. I won't be installing the AA clocking kit since I picked up a used AFW-style tubular crossmember with separate skid, and may just cannibalize the twin-stick shifter to build the triple-stick shifter for Jeepskate II/XL. The brakes work wonderfully!! I am very pleased with the difference the Navajo setup made...I think it actually stops better than my ZJ and Durango. I'll probably tackle the MegaSquirt EFI setup over the course of the Winter and am considering building a carputer (small PC setup to function like the systems in newer cars & SUV's...touch-screen, DVD, GPS, MP3's, etc) which will be installed full-time and be connected to the MegaSquirt for tuning. I've already purchased some of the components and had a few items from old systems laying around.

Fast forward to Winter 2005 and I replaced the Carter BBD with a Weber 32/36 kit that I picked up for $100 from a guy who sold his Jeep and had never gotten around to installing it. I also picked up an adapter that replaces the open element air filter and allows you to retain the factory air cleaner setup. I've got the carputer built...it's a little mini-ITX 1 GHz VIA based system in a DIN sized case with an M1-ATX 12-volt power supply board designed specifically for carputers and loaded with a stripped down version of Windows XP Pro. I just have to pick up an LCD touchscreen, install a carputer friendly GUI, and decide where I'm going to install the components.

This space for rent...

Stripped down & waiting for the fresh

engine.

Fire in the hole...

All hooked up & ready to run.

(That's factory cruise control on the fender).

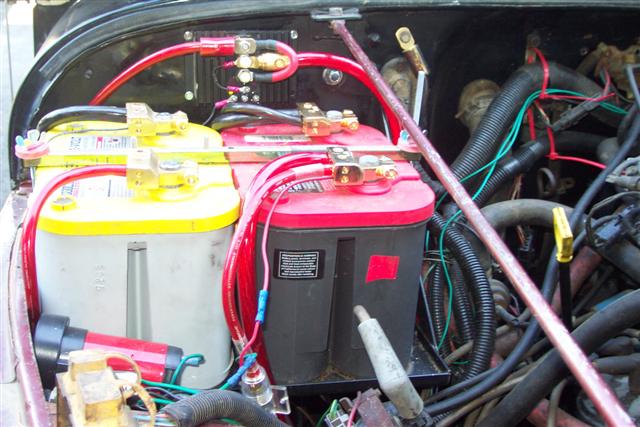

Juiced up...

New Optima Red Top, HD battery

terminals, upgraded power cables, TFI coil mounted to fender with bracket

from a Thunderbird.

Totally tubular...

Tubular crossmember w/bolt-on skid

plate (haven't installed the clocking ring or skid yet).

Remotely cooled...

Derale trans cooler tucked under the

rear seat area.

Doubling up...

Red & Yellow top Optimas teamed with a

Hellroaring isolator/combiner.